Ceramic Fiber Modules

Price 2000 INR/ Box

Ceramic Fiber Modules Specification

- Size

- Standard and customized sizes available

- Density

- 220 Gram per cubic centimeter(g/cm3)

- Thermal Conductivity

- 0.21-0.30 W/mK at 1000C

- Installation Guideline

- Anchored system; can be installed on hot or cold surfaces, easy mounting onto metallic shells

- Surface Treatment

- Pre-compressed and edge-sealed

- Feature

- Excellent thermal stability, lightweight, low heat storage, thermal shock resistant, easy to install

- Layer

- Multiple folded layers

- Coating Type

- Surface edge-sealed (on demand)

- Product Type

- Insulation Module

- Material

- High purity alumina-silicate ceramic fiber

- Tensile Strength

- Greater than 40 kPa

- Width

- 300 mm, 600 mm

- Thickness

- 100 mm, 150 mm, 200 mm

- Application

- Furnace lining, kiln insulation, boiler lagging, duct insulation, and backup insulation for high temperature applications

- Heat Conductivity

- Low

- Color

- White

- Max Withstanding Temperature

- 1260C to 1425C

Ceramic Fiber Modules Trade Information

- Minimum Order Quantity

- 10 Boxes

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Boxes Per Week

- Delivery Time

- 2 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Ceramic Fiber Modules

Product details

|

Colour |

white |

|

Classification temperature |

1260 |

Specification

|

Classification temperature degree C |

1260 |

1425 |

|

Colour |

White |

|

|

Fiber Diameter m |

2.5 to 4 |

|

|

Non Fiberous content by wt. (%) |

30 Max. |

|

|

Theoretical Density ( kg/m3) |

128160192 |

|

|

Chemical Composition (%) |

||

|

Al2O3 |

43-47 |

30-34 |

|

SiO2 |

53-58 |

48-55 |

|

Zr2O2 |

13-18 |

|

|

Other |

Traces |

Traces |

|

Module size (mm) |

150 x 305 x 305 |

|

|

175 x 305 x 305 |

||

|

200 x 305 x 305 |

||

|

225 x 305 x 305 |

||

|

250 x 305 x 305 |

||

|

275 x 305 x 305 |

||

|

305 x 305 x 305 |

||

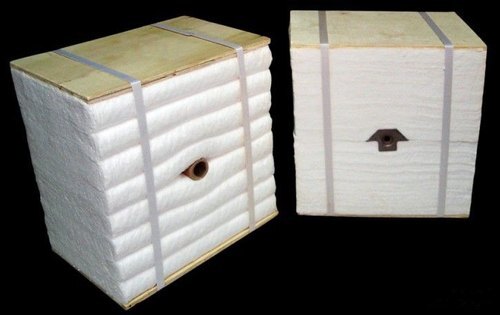

Superior Thermal Performance

Ceramic Fiber Modules deliver outstanding heat resistance and insulation, sustaining temperatures up to 1425C. Their low thermal conductivity (0.21-0.30 W/mK at 1000C) ensures minimal heat loss, making them perfect for demanding industrial applications. The modules' multi-layered, pre-compressed structure provides durability, while lightweight design enables easy handling and installation in furnaces, kilns, boilers, and ducts.

Reliable Chemical Resistance

Crafted from high-purity alumina-silicate ceramic fiber, these modules exhibit strong resistance to most industrial chemicals. The only exceptions are hydrofluoric acid, phosphoric acid, and strong alkalis. This resistance ensures stability and longevity within harsh process environments, reducing maintenance and replacement cycles for facility managers.

Installation Made Easy

The anchored module system fits seamlessly onto metallic shells and can be installed either on hot or cold surfaces. The zig-zag folding technique enhances mechanical strength while maintaining thermal stability. Modules arrive packed in robust wooden crates or cardboard boxes, simplifying logistics and storage before installation.

FAQ's of Ceramic Fiber Modules:

Q: How are Ceramic Fiber Modules installed in industrial settings?

A: Ceramic Fiber Modules are installed using an anchored system that allows easy mounting onto metallic shells. They can be fitted on both hot and cold surfaces due to their thermal shock resistance, simplifying the process for furnace or kiln insulation.Q: What benefits do these ceramic fiber modules offer compared to traditional insulation materials?

A: These modules feature excellent thermal stability, low thermal conductivity, lightweight construction, and low heat storage. Their robust resistance to most chemicals (except hydrofluoric and phosphoric acids, and strong alkalis) and high reusability make them superior for high-temperature insulation.Q: When is edge-sealing or surface treatment recommended for these modules?

A: Edge-sealing and surface treatment are recommended when additional protection against fiber detachment or chemical exposure is necessary. These options are available on demand and help enhance durability in aggressive environments.Q: Where can Ceramic Fiber Modules be used most effectively?

A: They are ideal for furnace linings, kiln insulation, boiler lagging, duct insulation, and as backup insulation in high temperature applications. Their versatility and custom sizing make them suitable across various industrial sectors.Q: What is the water absorption rate of these ceramic fiber modules?

A: Water absorption of the modules is less than 1% by weight, ensuring minimal impact from moisture in service, which is crucial for maintaining thermal insulation quality in humid conditions.Q: How does the module structure (zig-zag or accordion folded) influence performance?

A: The zig-zag or accordion module structure increases mechanical integrity and allows for easier installation. It maintains thermal insulation and improves resistance to thermal shock, optimizing performance in cyclic temperature settings.Q: Are these ceramic fiber modules reusable after high temperature exposure?

A: Yes, the modules are reusable under proper conditions. Their material formulation and structure make them durable for repeated use, provided they are not exposed to chemicals like hydrofluoric acid or strong alkalis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ceramic Fiber Modules Category

Ceramic Fiber Modules

Price 650 INR / Box

Minimum Order Quantity : 10 Boxes

Material : Ceramic

Color : White

Product Type : Ceramic Fiber Modules

Feature : Good Quality

Ceramic Fiber Module

Price 650 INR / Box

Minimum Order Quantity : 10 Boxes

Material : Ceramic

Color : White

Product Type : Ceramic Fiber Module

Feature : Good Quality

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry